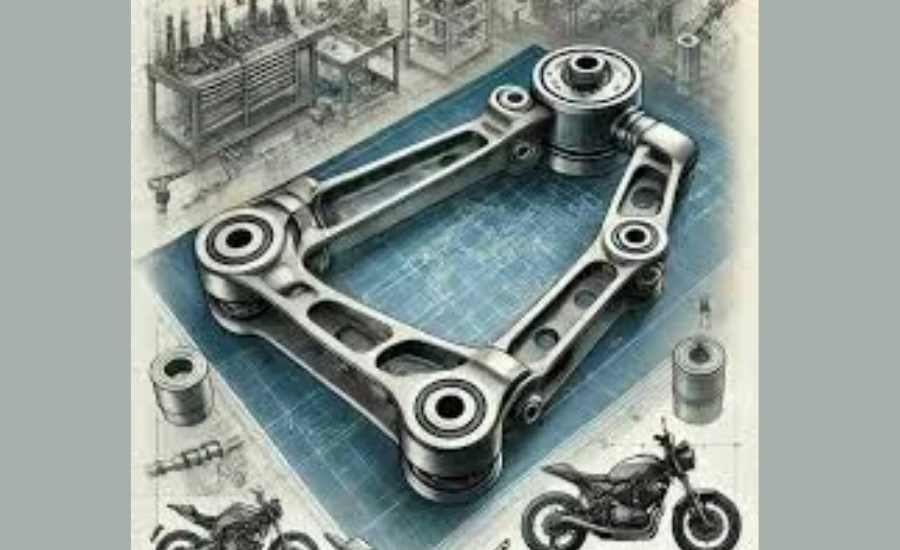

The Butler G4B25 22 swing arm is an essential component in various industries, particularly in those that involve heavy machinery and vehicles. Renowned for its precision, durability, and efficiency, this swing arm has become a favored choice in automotive and mechanical sectors. This guide offers a thorough exploration of the features and benefits of the Butler G4B25 22 swing arm, along with detailed insights into its installation process. By understanding these aspects, users can fully appreciate the swing arm’s capabilities and applications.

Designed for enhancing functionality and resilience in industrial settings, the Butler G4B25 22 swing arm excels in facilitating articulated movement within machines. This capability is crucial for operations such as tire changing and vehicle lifting, where precision is paramount. What sets the G4B25 22 model apart is its exceptional engineering, which delivers outstanding performance and extended service life. This makes it an invaluable asset for businesses seeking reliable and efficient equipment to support their operations.

What Is A Swing Arm?

A swing arm serves as a crucial element in machinery, enabling precise and controlled movement. This component is designed to support a range of motion, which is particularly important in automotive applications. By facilitating the necessary articulation, swing arms contribute significantly to the efficiency and effectiveness of various tools and equipment, making them indispensable in modern mechanics.

The Butler G4B25 22 swing arm is a prime example of this technology, widely utilized in vehicle lifts, tire changers, and other automotive machinery that demands robust movement. Its design promotes both stability and reliability, enabling smooth performance in challenging conditions. Whether lifting heavy vehicles or assisting in tire replacement, the Butler G4B25 22 swing arm provides the durability and performance required to meet the rigorous standards of the automotive industry.

Why Choose The Butler G4B25 22?

Exceptional Durability

Crafted from premium-grade materials, the Butler G4B25 22 is engineered to endure rigorous usage without compromising its structural integrity. This high durability ensures that it can handle the demands of heavy machinery while maintaining optimal performance over time.

Precision Engineering

The design of the Butler G4B25 22 enables seamless and articulated movements, making it an ideal choice for both intricate tasks and heavy-duty operations. This level of precision ensures reliable performance, whether the application involves delicate adjustments or the lifting of substantial loads.

Versatile Compatibility

One of the standout features of the Butler G4B25 22 is its compatibility with a wide range of machines. This versatility makes it a preferred option for professionals across various industries, allowing them to utilize the swing arm in diverse applications without the need for extensive modifications or specialized equipment.

Distinctive Features Of The Butler G4B25 22 Swing Arm

1. Robust Construction

The Butler G4B25 22 swing arm is meticulously crafted from high-grade steel, which provides exceptional strength and resilience, allowing it to effectively manage heavy workloads without sacrificing performance. This robust construction is a key factor in its widespread adoption across various industries that demand reliable and long-lasting equipment. Its ability to withstand the rigors of intense use makes it an invaluable component in settings where durability and performance are critical, ensuring that it meets the high standards required by professionals in the field.

2. Precision Bearings

Smooth operation is essential for swing arms, particularly in automotive machinery like tire changers, where precision and efficiency are critical. The Butler G4B25 22 is designed with high-precision bearings that facilitate effortless movement, significantly enhancing its performance. This feature not only ensures seamless operation but also minimizes wear and tear on the machine, prolonging its lifespan and reliability. By reducing friction during use, the Butler G4B25 22 helps maintain optimal functionality, making it a dependable choice for professionals who rely on the consistent performance of their equipment.

3. Advanced Articulation

The ability of a swing arm to move with precision in multiple directions is crucial for its effectiveness in various applications. The Butler G4B25 22 model has been expertly engineered to provide advanced articulation, enabling it to operate efficiently in a wide range of tasks. This design feature ensures that users can rely on the swing arm to deliver the exact movements needed, whether for delicate adjustments or more demanding functions.

This versatility makes the G4B25-22 particularly well-suited for tasks that demand a high level of accuracy. Professionals in fields such as automotive repair and maintenance benefit greatly from the swing arm’s precision capabilities, as it allows for meticulous work without compromising efficiency. With the G4B25-22, users can expect consistent performance, making it an invaluable tool for any job that requires careful handling and attention to detail.

4. Enhanced Load-Bearing Capacity

The Butler G4B25-22 swing arm is built with a sturdy design that allows it to bear heavy loads without bending or suffering any structural damage. This durability is a testament to its superior engineering, allowing it to handle a variety of loads with ease. Its enhanced load-bearing capacity makes it an excellent choice for a wide range of operations, from lightweight tasks to more demanding heavy-duty applications. As a result, professionals can rely on the G4B25-22 to perform effectively across different scenarios, ensuring safety and reliability in their work.

5. Corrosion Resistance

The Butler G4B25 22 swing arm boasts a specialized coating that provides excellent resistance to corrosion. This protective feature is crucial for maintaining the swing arm’s integrity, particularly in environments where it may be exposed to moisture or other corrosive elements. By preventing rust and degradation, the coating significantly extends the lifespan of the swing arm, ensuring it remains functional and reliable over time.

Moreover, the corrosion-resistant coating makes the G4B25-22 an ideal choice for demanding working conditions, such as automotive shops or outdoor settings. In these environments, equipment often faces exposure to various contaminants that can lead to wear and tear. With its robust protection against corrosion, the Butler G4B25 22 not only enhances operational efficiency but also reduces the need for frequent maintenance, ultimately saving time and costs for professionals who depend on durable and long-lasting tools.

Uses Of The Butler G4B25 22 Swing Arm

The Butler G4B25 22 swing arm is highly versatile and finds applications in a variety of industries. Its robust design and reliable performance make it an essential component in sectors that require precise movement and heavy load handling. From automotive repair shops to manufacturing facilities, this swing arm has become a trusted choice for professionals looking for durability and efficiency in their equipment.

Some of the key sectors where the G4B25 22 is widely utilized include automotive services, where it is integral to tire changers and vehicle lifts, ensuring smooth and safe operations. Additionally, it is valuable in construction and industrial machinery, supporting tasks that demand both strength and precision. With its adaptability, the Butler G4B25 22 swing arm continues to meet the diverse needs of various industries, making it an indispensable tool for many professionals.

1. Automotive Repair And Maintenance

The Butler G4B25 22 swing arm is primarily utilized in automotive workshops, where it plays a vital role in equipment such as tire changers and vehicle lifts. Its precision engineering ensures smooth and accurate movements, which are essential for safely lifting vehicles and efficiently changing tires. This capability not only enhances operational safety but also contributes to a streamlined workflow in busy automotive environments. Moreover, the swing arm’s remarkable durability allows it to withstand the rigors of frequent use, making it an indispensable tool for professionals who require reliable performance in their daily tasks. Overall, the G4B25-22 is crucial for enhancing productivity and service quality in automotive service operations.

2. Industrial Machinery

The Butler G4B25 22 swing arm is also widely employed in industrial settings, where the machinery relies on dependable components for repetitive movements. Its robust construction allows it to endure constant use without compromising its functionality, making it an ideal choice for environments that demand high performance and reliability. This resilience is particularly beneficial in production lines and manufacturing processes, where equipment is subjected to rigorous operating conditions. By ensuring consistent operation, the G4B25-22 contributes to enhanced efficiency and productivity in industrial applications, proving to be an invaluable asset for businesses that prioritize durability and operational excellence in their machinery.

3. Heavy Equipment Manufacturing

In the manufacturing of heavy equipment, the Butler G4B25 22 swing arm is essential for facilitating the smooth operation of various moving parts. Its robust strength and superior articulation enable it to effectively handle the demands of complex production lines, where precision and reliability are paramount. By ensuring that components move seamlessly together, the G4B25 22 enhances the overall efficiency of manufacturing processes. This vital swing arm not only contributes to the effective assembly of heavy machinery but also plays a crucial role in minimizing downtime and maintenance.

4. Construction Machinery

Construction equipment frequently demands reliable swing arms capable of managing heavy loads and enduring repetitive movements. The Butler G4B25 22 swing arm stands out in this regard, thanks to its exceptional load-bearing capacity and robust durability. Designed to withstand the harsh conditions typical in construction environments, the G4B25-22 effectively supports the operational needs of various machinery, from excavators to cranes. Its ability to perform consistently under significant stress not only enhances the efficiency of construction tasks but also ensures the safety and reliability of the equipment. As a result, the G4B25-22 is an ideal choice for construction professionals who require dependable components to optimize their heavy machinery.

Care And Maintenance Guidelines For The Butler G4B25 22 Swing Arm

To ensure that the Butler G4B25 22 swing arm operates at peak performance, regular maintenance is crucial. Proper care not only extends the life of the swing arm but also enhances its efficiency and reliability in various applications. Regular inspections should be conducted to identify any signs of wear or damage, and any issues should be addressed promptly to prevent further complications. Additionally, keeping the swing arm clean from debris and contaminants can significantly improve its functionality and longevity.

Incorporating lubrication into your maintenance routine is also vital for the smooth operation of the swing arm. Applying high-quality lubricants to the bearings and pivot points helps reduce friction, ensuring seamless movement and minimizing wear. Furthermore, following the manufacturer’s guidelines for maintenance schedules and procedures will provide valuable insights on how to keep the G4B25 22 in optimal condition. By adhering to these maintenance tips, users can enjoy long-term performance and reliability from their Butler G4B25 22 swing arm.

1. Regular Lubrication

Regularly lubricating the bearings and other moving parts of the Butler G4B25 22 swing arm is essential for preventing excessive wear and ensuring smooth operation. By applying high-quality lubricants, you can significantly reduce friction, which helps maintain the efficiency and performance of the swing arm over time. It is important to choose lubricants that are specifically designed for the materials used in the swing arm to avoid any build-up of residue that could impede movement or lead to mechanical issues. This proactive maintenance practice not only extends the lifespan of the swing arm but also contributes to its reliability in demanding applications, making it a key component for professionals who rely on optimal performance in their equipment.

2. Inspect For Wear And Tear

Regular inspections of the Butler G4B25 22 swing arm are crucial for identifying signs of wear, such as cracks, bending, or damage to the bearings. By diligently checking for these issues, you can detect potential problems early on, which is essential for preventing more significant and costly repairs in the future. This proactive approach not only safeguards the integrity of the swing arm but also ensures uninterrupted performance in various applications. Establishing a routine inspection schedule will help maintain the swing arm’s reliability and longevity, allowing you to address any concerns before they escalate into major complications that could affect the overall efficiency of your equipment.

3. Clean The Swing Arm

Over time, dirt and debris can accumulate on the Butler G4B25 22 swing arm, potentially leading to corrosion or damage that compromises its performance. Regular cleaning is essential, particularly in high-dust environments where contaminants can build up more quickly. By removing dirt and grime, you not only enhance the swing arm’s appearance but also help preserve its integrity and functionality. Establishing a routine cleaning schedule will ensure that the swing arm remains in optimal condition, allowing it to perform effectively in various applications. This simple maintenance step is vital for extending the lifespan of the swing arm and preventing issues that could arise from neglecting its upkeep.

4. Check Bolts And Fasteners

Over time, the continuous movement of machinery can cause bolts and fasteners to loosen, potentially compromising the stability and performance of the Butler G4B25 22 swing arm. It is crucial to regularly inspect these components and tighten any loose fasteners to ensure that the swing arm remains securely in place. This simple maintenance step not only enhances the safety and reliability of the equipment but also helps prevent unnecessary wear and tear that could result from a compromised assembly. By incorporating this practice into your routine maintenance schedule, you can significantly extend the life of the swing arm and maintain optimal operational efficiency in various applications.

Frequently Encountered Problems And Solutions Aor The Butler G4B25 22 Swing Arm

Like any mechanical component, the Butler G4B25 22 swing arm may encounter various issues throughout its operational life. Understanding these common problems and knowing how to troubleshoot them is essential for maintaining optimal performance and ensuring the longevity of the swing arm. Typical issues may include unusual noises during operation, difficulty in movement, or signs of excessive wear. By familiarizing yourself with these potential problems, you can take proactive measures to address them promptly, ensuring that the swing arm continues to function efficiently and safely. Regular maintenance, inspections, and troubleshooting will not only help you identify issues early on but also prevent them from escalating into more significant complications that could impact overall equipment performance.

1. Stiff Movement

If the Butler G4B25 22 swing arm is moving stiffly or not at all, it’s essential to inspect the bearings for signs of wear or the presence of debris that could be hindering movement. Accumulated dirt or damaged bearings can significantly affect the swing arm’s functionality, leading to stiffness or complete immobility. Additionally, applying lubrication can often resolve this issue by reducing friction and facilitating smoother movement. Ensuring that the bearings are clean and well-lubricated not only enhances the swing arm’s performance but also helps prevent further wear and potential mechanical failures, allowing it to operate efficiently in various applications. Regular maintenance and prompt attention to these concerns will contribute to the longevity and reliability of the swing arm.

2. Noise During Operation

Excessive noise during the operation of the Butler G4B25 22 swing arm can be a clear indication of underlying issues, particularly related to the bearings or alignment. Such noises often suggest that the bearings may be worn out or misaligned, which can compromise the swing arm’s functionality. It’s crucial to inspect the swing arm for any visible signs of damage, such as cracks or deformities, that could be contributing to the noise. If worn parts are identified during the inspection, it’s important to replace them promptly to restore optimal performance. Addressing these concerns not only minimizes operational noise but also enhances the overall efficiency and longevity of the swing arm, ensuring reliable performance in various applications. Regular maintenance and attentive monitoring can prevent minor issues from developing into significant problems, thereby safeguarding the integrity of the equipment.

3. Uneven Load Bearing

If the Butler G4B25 22 swing arm is not bearing weight evenly, it’s essential to investigate potential alignment issues that may be affecting its performance. Uneven weight distribution can lead to unnecessary strain on the swing arm and other connected components, potentially causing damage over time. To address this, carefully check the alignment of the swing arm and look for any signs that it may be out of position. If misalignment is detected, it may be necessary to readjust the swing arm to restore proper weight distribution. Ensuring that the swing arm is correctly aligned not only improves its operational efficiency but also enhances the overall stability and safety of the equipment, ultimately prolonging its lifespan and reliability in various applications. Regular inspections and adjustments can help maintain optimal performance and prevent future complications.

FAQS About The Butler G4B25 22 Swing Arm

Q: What applications is the Butler G4B25-22 swing arm suitable for?

A: The Butler G4B25 22 swing arm is versatile and suited for multiple uses, such as in automotive repair shops, industrial machinery, and construction tools. It excels in tire changers, vehicle lifts, and other systems that require precise and robust movement.

Q: What materials are used in the construction of the G4B25-22 swing arm?

A: The swing arm is constructed from high-grade steel, which ensures exceptional strength and durability. This robust material choice allows it to withstand heavy loads and frequent use without compromising performance.

Q: How do I maintain the Butler G4B25 22 swing arm?

A: To maintain the swing arm, perform regular inspections for signs of wear, clean it to remove dirt and debris, lubricate moving parts, and check for loose bolts and fasteners. Following these maintenance practices will help ensure its longevity and optimal performance.

Q: What should I do if the swing arm is making unusual noises during operation?

A: Unusual noises may indicate potential issues with the bearings or alignment. Inspect the swing arm for visible damage and check the bearings for wear. If necessary, replace worn parts and ensure proper alignment to restore quiet operation.

Q: Can the G4B25-22 swing arm be used in high-dust environments?

A: Yes, the Butler G4B25 22 swing arm can be used in high-dust environments. However, regular cleaning is essential to prevent dirt accumulation, which can lead to corrosion or damage. Ensure to follow a routine maintenance schedule to keep it functioning optimally.

Conclusion

The Butler G4B25 22 swing arm is a crucial component for those seeking to enhance the efficiency and durability of their automotive or industrial machinery. With its precision engineering, this swing arm provides smooth, accurate movements that are essential for various applications. Its robust construction ensures that it can withstand the rigors of heavy use, making it a dependable choice in demanding environments. Whether used in tire changers, vehicle lifts, or industrial equipment, the G4B25-22 stands out for its versatility and performance, establishing itself as a top choice among professionals in the industry.

To maximize the benefits of the G4B25-22 swing arm, it is important for users to adhere to proper installation and maintenance guidelines. Regular upkeep, including inspections, lubrication, and alignment checks, will help ensure long-lasting performance and reliability. By proactively addressing potential issues and maintaining the swing arm’s condition, users can significantly extend its lifespan and maintain optimal functionality. Ultimately, investing in the Butler G4B25 22 swing arm not only improves operational efficiency but also contributes to the overall effectiveness of automotive and industrial machinery, making it a valuable addition to any workspace.

For continuous updates and alerts, be sure to stay connected: Tribune Tribune!