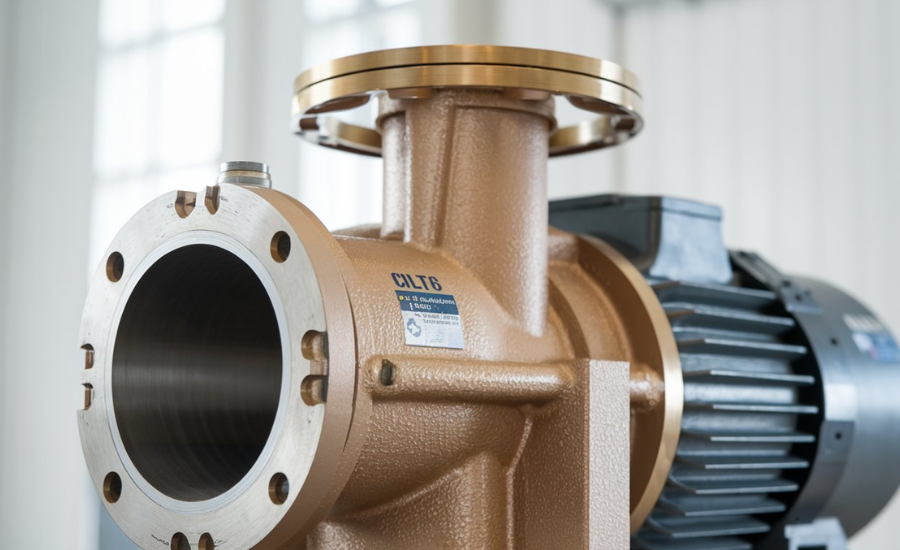

The Allweiler CLT6 pump no wear ring is revolutionizing the landscape of fluid handling, setting a new standard for efficiency and reliability. Unlike traditional pumps that often rely on wear rings—components that can cause friction and wear—the Allweiler CLT6 eliminates this part entirely. This thoughtful design choice significantly reduces mechanical issues, allowing the pump to operate more smoothly and extend its lifespan. For industries that demand consistent performance from their equipment, this means a reliable pumping solution that minimizes the need for frequent maintenance.

With the Allweiler CLT6 pump no wear ring, businesses gain access to a highly efficient machine that saves both time and resources. The reduction in parts not only lessens the likelihood of breakdowns but also simplifies the overall maintenance process. Companies can dedicate their efforts to core operations rather than worrying about the upkeep of their pumps. This innovative approach is ideal for any organization seeking to enhance its pumping systems while ensuring uninterrupted workflows and optimal performance.

Understanding The Allweiler CLT6 Pump No Wear Ring

The Allweiler CLT6 pump no wear ring is a revolutionary piece of equipment that sets itself apart in the world of fluid handling. Unlike traditional pumps that utilize wear rings—essential components designed to help maintain efficiency—this innovative pump completely omits this part from its design. This elimination results in a streamlined construction with fewer components that are susceptible to damage or wear. As a result, the Allweiler CLT6 is not only more reliable but also has an extended operational lifespan, reducing the frequency of repairs and downtime for businesses.

Reduced Friction for Enhanced Performance

One of the significant advantages of the Allweiler CLT6 pump is its ability to minimize friction. In conventional pumps, wear rings create friction as moving parts come into contact with each other, leading to wear and tear over time. By eliminating the wear ring, the Allweiler CLT6 significantly reduces this friction, enabling smoother operation and more efficient fluid transfer. This reduction in friction is particularly beneficial for industries that depend on pumps to perform consistently and reliably under various conditions.

Simplified Maintenance and Operation

Another noteworthy feature of the Allweiler CLT6 pump is its maintenance-friendly design. With no wear ring to monitor or replace, maintenance becomes a more straightforward and less time-consuming process. Companies can allocate their resources more efficiently, spending less time on upkeep and more time on productive operations. This user-friendly aspect of the Allweiler CLT6 has made it a preferred choice among many organizations looking to enhance their fluid handling systems.

Commitment to Innovative Technology

The design of the Allweiler CLT6 pump underscores the company’s dedication to advancing pump technology. By focusing on efficiency, reliability, and ease of use, Allweiler has created a product that is well-suited for the demands of modern industries. Organizations searching for dependable pumping solutions can confidently turn to the Allweiler CLT6 pump, knowing it has been engineered to meet their needs both now and in the future.

In conclusion, the Allweiler CLT6 pump no wear ring not only provides significant operational benefits but also reflects a commitment to innovation in fluid handling. This makes it a valuable asset for any business seeking reliable and efficient pumping solutions.

Why The Allweiler CLT6 Pump No Wear Ring Is A Game Changer

The Allweiler CLT6 pump no wear ring represents a significant advancement in fluid handling technology, primarily due to its energy efficiency. One of its standout features is the reduced internal friction that results from the absence of a wear ring. This innovative design means the pump requires less power to operate, leading to notable energy savings. For businesses aiming to minimize operating costs, this translates to lower energy bills over time. As energy savings accumulate, companies can redirect those resources toward other critical areas of their operations, enhancing overall profitability.

In addition to its energy efficiency, the durability of the Allweiler CLT6 pump sets it apart from traditional pumps. With fewer components that are prone to wear and tear, this pump has a longer operational lifespan, making it a reliable choice for industries that depend on continuous performance over extended periods. Organizations investing in the Allweiler CLT6 can rest assured that they are selecting a robust solution that will withstand the test of time, reducing the frequency of replacements and associated downtime. This combination of energy efficiency and durability positions the Allweiler CLT6 pump as a valuable asset for companies seeking sustainable and dependable fluid handling solutions.

Benefits Of The Allweiler CLT6 Pump

Energy Efficiency

One of the most significant advantages of the Allweiler CLT6 pump is its energy efficiency. By eliminating the wear ring, the pump operates with reduced internal friction, which translates to lower power consumption. This not only helps businesses cut down on their energy bills but also supports sustainability initiatives by minimizing their overall carbon footprint. With the Allweiler CLT6, companies can achieve more with less energy, leading to significant cost savings over time.

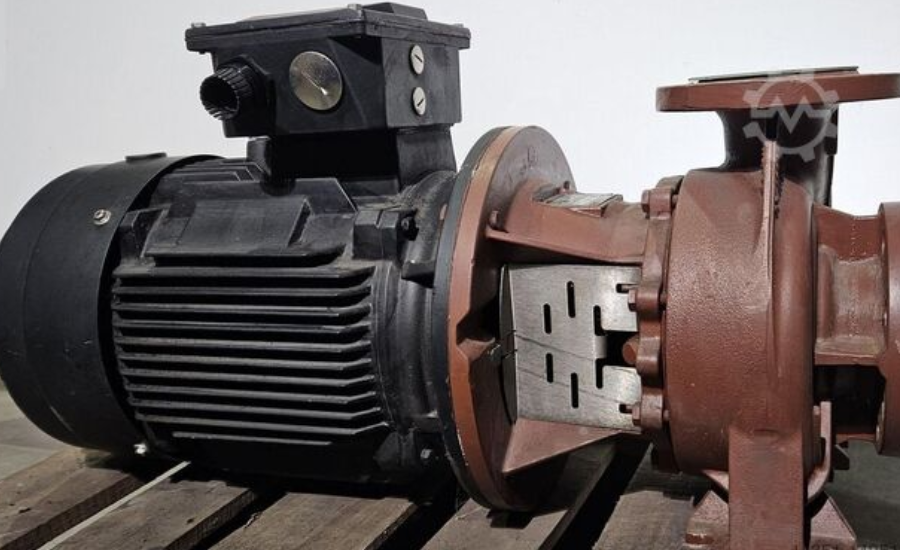

Durability

The durability of the Allweiler CLT6 pump is another key feature that sets it apart from traditional pumps. With fewer moving parts that can wear out, the pump is designed to last longer and operate reliably even in demanding conditions. This longevity is particularly beneficial for industries where equipment failure can result in costly downtime. Organizations can invest in the Allweiler CLT6 with confidence, knowing that it is built to withstand rigorous use and deliver consistent performance over the years.

Low Maintenance

Maintenance is often a significant concern for businesses that rely on pumping systems. The Allweiler CLT6 pump simplifies this aspect by reducing the number of components that require regular checks and replacements. Fewer parts mean less time spent on maintenance tasks, allowing operators to focus on more critical areas of their operations. This streamlined maintenance approach not only enhances operational efficiency but also reduces labor costs associated with pump upkeep.

Versatility

Moreover, the Allweiler CLT6 pump boasts remarkable versatility, making it suitable for a wide range of applications across various industries. Whether in chemical processing, water treatment, food and beverage production, or other sectors, this pump can handle different types of fluids with ease. Its adaptability ensures that it can seamlessly integrate into existing systems without any issues, providing companies with a flexible and reliable pumping solution tailored to their specific needs. This versatility positions the Allweiler CLT6 as an ideal choice for organizations seeking a dependable pump that can meet diverse operational demands.

How The Allweiler CLT6 Pump No Wear Ring Works

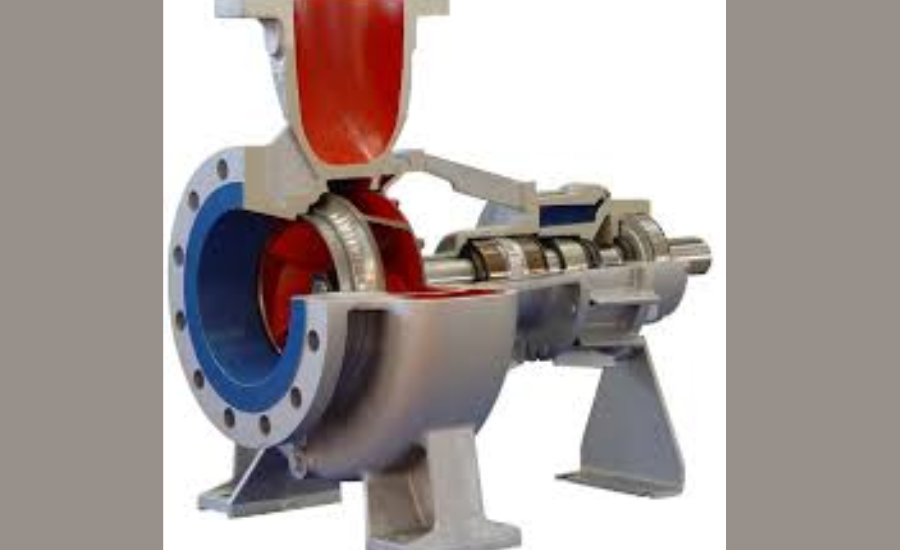

Innovative Design and Sealing System

The Allweiler CLT6 pump showcases a design that is both straightforward and highly effective, prioritizing functionality without unnecessary complexity. By eliminating the traditional wear ring, this pump employs a cutting-edge sealing system that ensures fluids remain contained while simultaneously minimizing friction. This innovative approach not only leads to smoother operation but also enhances overall efficiency, allowing the pump to perform optimally across various applications. The simplicity of the design means fewer components that can fail, contributing to the pump’s reliability and making it an attractive choice for industries that require consistent performance.

Advanced Materials for Enhanced Performance

In addition to its unique design, the Allweiler CLT6 pump is constructed with advanced materials that significantly boost its performance capabilities. These specially selected materials are engineered to withstand a wide range of fluid types, from viscous substances to lighter liquids, making the pump incredibly versatile. This adaptability allows it to function effectively in diverse environments, whether in chemical processing, water treatment, or food production. By meeting the demands of different industries, the Allweiler CLT6 pump proves itself as a reliable solution for companies seeking a robust pumping system that can handle the rigors of various operational conditions.

How It Works

Innovative Sealing System

The Allweiler CLT6 pump utilizes a state-of-the-art sealing system designed to effectively contain fluids without the need for a wear ring. This advanced mechanism not only prevents leaks but also maintains the integrity of the pumped materials. By eliminating the wear ring, the pump significantly reduces the potential for mechanical failures that can arise from wear and tear. This ensures a more reliable operation and peace of mind for operators, allowing them to focus on their core activities without the constant worry of maintenance issues.

Robust Advanced Materials

Constructed from high-quality, advanced materials, the Allweiler CLT6 pump is engineered to withstand a diverse range of fluids, from thick and viscous substances to more delicate liquids. These materials are specifically chosen for their durability and resistance to corrosion, which enhances the pump’s longevity and reliability. This adaptability makes the CLT6 pump suitable for various industrial applications, including chemical processing, water treatment, and food production, where it can handle different fluid characteristics without compromising performance.

Enhanced Operational Efficiency

One of the standout features of the Allweiler CLT6 pump is its ability to reduce friction during operation, leading to smoother performance and increased efficiency. With fewer moving parts and a streamlined design, this pump minimizes energy consumption while maximizing output. The reduced friction not only enhances the pump’s overall performance but also contributes to lower operational costs for businesses. As a result, companies can expect improved productivity and greater returns on their investment when using this innovative pumping solution.

The Benefits Of Using The Allweiler CLT6 Pump No Wear Ring

Cost Savings and Longevity

Utilizing the Allweiler CLT6 pump without a wear ring offers numerous financial advantages for businesses. One of the most significant benefits is the reduction in overall costs associated with maintenance and repairs. Traditional pumps often require frequent servicing due to wear and tear on critical components like wear rings. However, the innovative design of the CLT6 pump minimizes these concerns, resulting in a longer lifespan and less downtime for maintenance. This not only translates to direct savings on repair and replacement costs but also allows companies to allocate their resources more effectively. By investing in the Allweiler CLT6 pump, businesses can enhance their bottom line while enjoying the peace of mind that comes with a reliable pumping solution.

Enhanced Efficiency and Productivity

In addition to cost savings, the Allweiler CLT6 pump significantly boosts operational efficiency. Its unique design enables it to move fluids more quickly and effectively than traditional pumps. This increased efficiency can lead to heightened productivity across various processes within a business. When pumps operate at optimal levels, it allows companies to produce more output with less effort, streamlining operations and maximizing resource utilization. Ultimately, the Allweiler CLT6 pump not only improves the flow of materials but also empowers businesses to achieve greater results with enhanced reliability and effectiveness. This combination of efficiency and cost-effectiveness makes the CLT6 pump a valuable asset for any organization seeking to optimize their fluid handling systems.

Benefits Of The Allweiler CLT6 Pump

Cost Savings and Reduced Repair Costs

One of the standout features of the Allweiler CLT6 pump is its ability to drive significant cost savings for businesses. By eliminating the need for a wear ring, this innovative pump minimizes the frequency of repairs and the associated costs. Traditional pumps often require ongoing maintenance to address wear and tear, which can add up over time. In contrast, the CLT6’s design focuses on longevity and reliability, resulting in fewer breakdowns and lower repair expenses. This not only enhances financial stability for companies but also allows them to invest those savings into other critical areas of their operations.

Enhanced Efficiency and Fluid Movement

The Allweiler CLT6 pump is engineered for improved efficiency, enabling it to move fluids more rapidly than conventional pumps. This streamlined operation ensures that processes run smoothly and swiftly, making it an ideal choice for industries where time is of the essence. By optimizing fluid movement, businesses can reduce delays and bottlenecks in their workflows, contributing to a more effective overall operation. The pump’s efficient performance not only enhances the speed of production but also supports a better allocation of resources, further solidifying its position as a valuable tool for any organization.

Increased Productivity and Operational Output

With its reliable design and fast fluid movement, the Allweiler CLT6 pump plays a crucial role in increasing overall productivity. By helping businesses achieve more in less time, this pump becomes an essential asset in any operational environment. Enhanced productivity translates to higher output levels, allowing companies to meet growing demands without compromising quality or efficiency. The ability to handle increased workloads seamlessly positions the CLT6 pump as a vital component in a company’s strategy for growth and success.

Eco-Friendly Design and Sustainability

In addition to its financial and operational benefits, the Allweiler CLT6 pump also supports environmental sustainability. Its energy-efficient design means that it consumes less power during operation, contributing to a reduction in a company’s carbon footprint. As more businesses seek to implement sustainable practices, the CLT6 pump emerges as an environmentally responsible choice. By investing in this pump, companies can align their operations with eco-friendly initiatives, demonstrating a commitment to sustainability while enjoying the economic advantages it offers. This dual focus on efficiency and environmental responsibility makes the Allweiler CLT6 pump a forward-thinking solution for today’s conscientious businesses.

Simplifying Maintenance With The Allweiler CLT6 Pump No Wear Ring

Simplified Maintenance Process

Maintaining the Allweiler CLT6 pump without a wear ring offers significant advantages over traditional pump designs. The absence of a wear ring means that operators no longer have to perform regular checks or replacements for this component, which is often a source of concern in other pumps. This streamlined approach reduces the number of parts that require attention, allowing maintenance teams to focus on more critical tasks. As a result, operators can allocate their time and resources more effectively, leading to a more efficient maintenance process overall.

Minimizing Downtime and Operational Disruptions

Regular maintenance can often be a burden for businesses, leading to costly downtime that interrupts production and increases operational costs. The Allweiler CLT6 pump mitigates these challenges by simplifying maintenance requirements. By minimizing the frequency of necessary checks and repairs, this pump enables companies to maintain continuous operations without the interruptions commonly associated with traditional pumps. This reliability not only enhances productivity but also supports a smoother workflow, allowing businesses to focus on their core activities without the worry of unexpected maintenance-related disruptions. The result is a more efficient, cost-effective approach to fluid handling that benefits both operations and the bottom line.

Maintenance Simplified

Fewer Components for Streamlined Maintenance

One of the standout features of the Allweiler CLT6 pump is its design, which incorporates fewer components compared to traditional pump models. This simplified structure means there are fewer parts for operators to monitor and replace regularly. Consequently, maintenance routines become less complex, allowing maintenance teams to streamline their processes. This reduction in components not only saves time but also lessens the chances of component failure, leading to a more reliable pumping system.

Minimizing Downtime for Continuous Operations

Another significant advantage of the Allweiler CLT6 pump is its ability to minimize downtime. With fewer parts to check and maintain, companies can keep their production lines running smoothly without interruptions. This uninterrupted flow of operations is critical for meeting production targets and maintaining profitability. By reducing the frequency and complexity of maintenance tasks, businesses can focus on their core activities, enhancing overall productivity and efficiency.

Less Hassle for Operators

The design of the Allweiler CLT6 pump alleviates many of the hassles associated with traditional pump maintenance. Operators can concentrate on more important tasks rather than getting bogged down by frequent maintenance checks. This allows for better allocation of resources and a more proactive approach to operations. By making maintenance easier, the Allweiler CLT6 pump empowers companies to achieve their objectives with greater ease and confidence.

FAQs

Q: What is the Allweiler CLT6 pump without a wear ring?

A: The allweiler clt6 pump no wear ring is a cutting-edge fluid handling solution that eliminates the traditional wear ring, resulting in lower friction, enhanced reliability, and decreased maintenance requirements.

Q: How does not having a wear ring benefit the pump?

A: By removing the wear ring, the pump has fewer components that can wear out, which increases its durability and reduces the need for maintenance over time, ultimately improving its overall efficiency.

Q: Which industries can use the Allweiler CLT6 pump?

A: The Allweiler CLT6 pump is versatile and suitable for various sectors, including chemical processing, water treatment, and any application that requires dependable fluid handling.

Q: What are the main advantages of using the Allweiler CLT6 pump?

A: Key advantages include energy efficiency, cost savings, enhanced operational efficiency, increased productivity, and an eco-friendly profile due to its lower energy consumption.

Q: How does the Allweiler CLT6 pump make maintenance easier?

A: The pump’s design reduces the number of parts that need regular checks and replacements, enabling operators to focus more on productive tasks rather than maintenance.

Conclusion

The allweiler clt6 pump no wear ring without a wear ring represents a groundbreaking advancement in fluid handling technology. By removing the wear ring, this pump significantly boosts reliability, efficiency, and durability while also making maintenance much easier. Industries can take advantage of reduced downtime and lower operational costs, leading to greater productivity. With its eco-friendly design and versatility across various applications, the Allweiler CLT6 pump is an ideal choice for businesses seeking to enhance their pumping systems while prioritizing sustainability.

To stay informed about all the latest news and alerts, make sure to visit us regularly: Tribune Tribune!